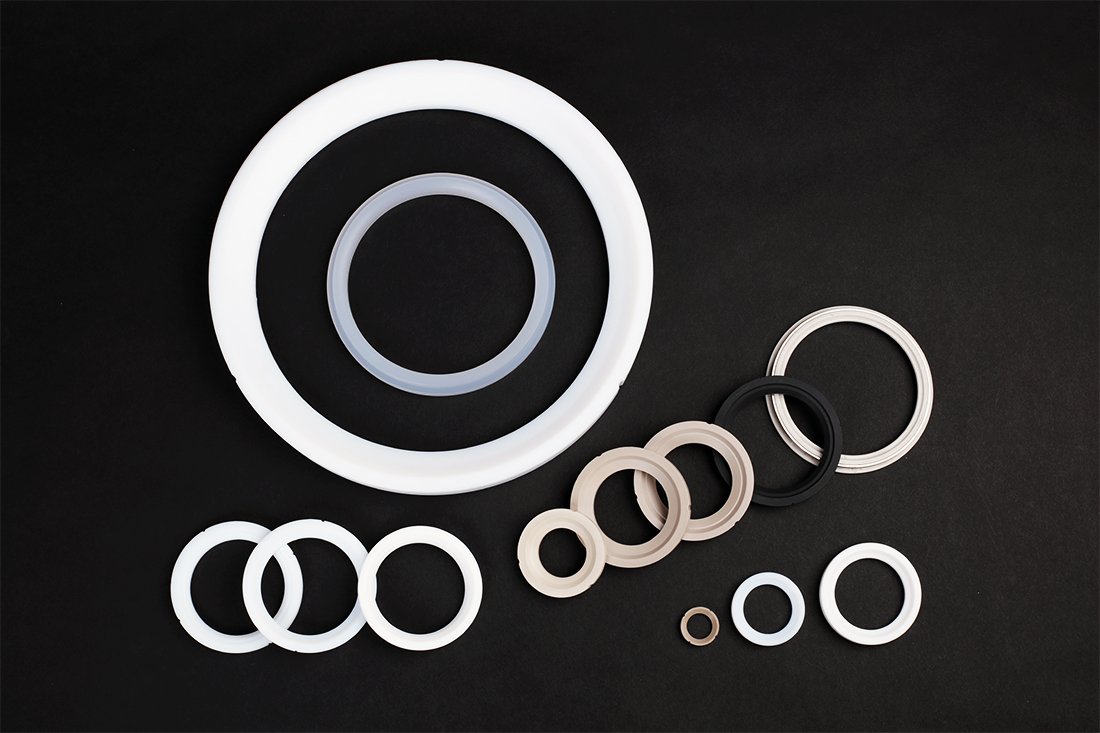

VALVE SEAT

Valve seat ring is to maintain the valve sealing strength and promote the sealing of the key components of leak-free. Applicable valve type: Fixed ball valve, floating ball valve, sluice valve, butterfly valve, regulating valve, etc.

其他信息

| Product Name | Valve Seat |

|---|---|

| Material | M-PTFE, NYLON, PCTFE, PEEK, POM, PTFE, RPTFE |

| Temperature | -196 ~ 260℃ |

| Pressure | 150~2500LB |

| Color | According to the materials |

PROCESS DESCRIPTION

Product Details:

VALVE SEAT

The valve seat is a crucial part of maintaining the strength of the seal within the valve and facilitating a seal that is free of leaks.

THE FUNCTIONS

Compression gas sealing. The purpose is to prevent compressed gasses or combustion gases from escaping into the manifold.

Heat transfer, allowing a certain amount of heat to move through the valve into the cylinder head.

It is maintaining the strength of the seal when the valve has been mounted. It is crucial where the quality and integrity of the valve seat.

Reduce wear-resistance. The entire valve seat must be able to withstand the pressure of high heat and high loads.

Strong ability to keep work processes low to keep operating within a reasonable cost.

Finally, the seats and rings must be easy enough to machine to prepare them for specific applications.

APPLICATIONS

Fixed ball valve, floating ball valve, sluice valve, butterfly valve, regulating valve, etc.